The Global Ultra-precise parts Dong Bang Tech Co., Ltd.

We Repay Your Trust with Quality

COMPANY

CEO Greeting

Dong Bang Tech assures customer satisfaction through finest quality products.

Greetings!

Dong Bang Tech, specializing in automotive precision parts, was established in 1982, and has become a trusted producer thanks to our customers.

We consider trust to be our most valuable policy.

We would like to be a business trusted by our customers by providing products of the finest quality, best prices, and by keeping a punctual supply date. To do so, we invest a lot of resources into developing new, advanced technologies and processes. Our ethical policy also prioritizes the environment, safety, and human rights to fulfill our responsibility to society. Our staff will work as a single entity to ensure that our efforts will provide a better experience for our customers.

Thank you for your continued support.

Kim, Dong-Jo Chief Executive Officer

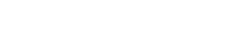

History

1990

| 1982 | Established Dong Bang Precision |

|---|---|

| 1985 | Developed LPG Air Valve |

2003

| 2000 | Developed Industrial Supplies |

|---|---|

| 2002 | Conversion into Dong Bang Tech Co. Ltd. |

| 2003 | ISO9001 Certification Received |

2011

| 2011 | Certified as a Parts/Materials Specialty Business |

|---|---|

| Certified as a Promising Export Firm | |

| INNO-BZ Certification Received | |

| Certified as a Startup Firm |

2013

| 2013 | 3 Government Technological Development Projects Carried Out |

|---|---|

| RSM SESE Tier-2 Certification Received | |

| GMK QSB Certification Received | |

| ISO/TS 16949 Certification Received |

2017

| 2015 | New Excellent Technology Certification (No. 0915) Ministry of Trade, Industry and Energy--Electronic Variable Pressure Regulation through Bypass Flow Control of Decompressor of CNG Cars |

|---|

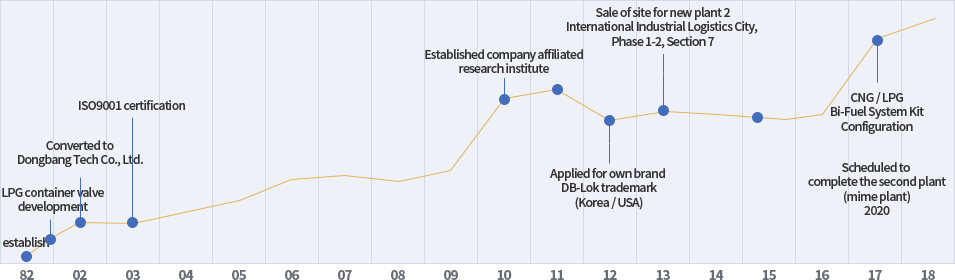

Corporation Structure

Factory view

Location

80, Hakgam-daero 178beon-gil, Sasang-gu, Busan, Republic of Korea

- TEL. +82-51-323-2693

- FAX. +82-51-328-2593

Facilities Status

Auto CNC M/C

PUMA ST20G

MCT Machining Center

DNM 400

Auto CNC M/C

XD26H

Auto CNC M/C

XE20

Major Development Equipment Status

Cleanroom

Ultrasonic Cleaner

Ultrasonic Cleaner

Gloove Box

Vacuum dryer

Vacuum packing machine

Optical microscope

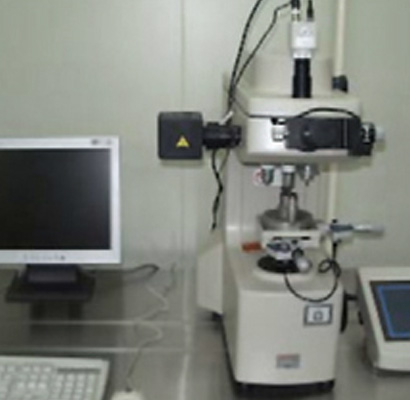

Hardness tester

Nut Insertion Tester

Surface Roughness Tester

Facility/Equipment Status

- AUTO M / C Φ20

- AUTO M / C Φ25

- AUTO M / C Φ35

- AUTO M / C Φ17

- AUTO M / C Φ18

- CNG M / C

- 6-axis multi-axis M/C

- Press Machine

- TAP M/C Machine

- External Diameter Processing Machine

- Chamfering Machine

- VISION Tester

- Barrel Grinding Machine

- Clean Room 9 (Class 100) Construction Complete

Measuring Instruments Inventory Status

- Contour Measurement Instrument

- Projector

- Surface Roughness Tester

- DIGITAL V / C

- HEIGHT GAUGE

- DIAL GAUGE

- V-BLOCK

- PLUG GAUGE

- RING GAUGE

- OUTER DIAMETER

- BORE GAUGE

- PIN GAUGE

- Saltwater Spray Tester

- Hardness Tester

- Sample Cutting Machine

- Water Purification System (D.I Water)

- Ultrasonic Cleaner (4 Sump)

- Vacuum Dryer (N2)

- Insert Nut Indentation Tester

- Tensile Strength Tester

- Digital Torque Wrench

Investment Plan for New Equipment

New Equipment Review

- Forging Press (300 Tons)

- 2 MCTs

- Automatic Chuck

- High-frequency Heater (500 Kw)

Testing Equipment

- High Pressure, Low Pressure External Leak Tester